Specialist doors for cleanrooms

Pharmaceutical clean room doors for manufacturing and research facilities

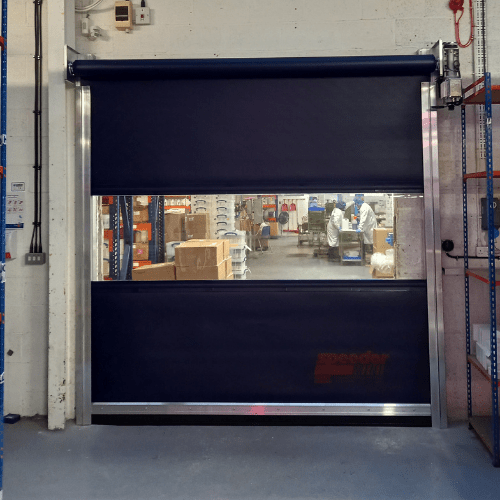

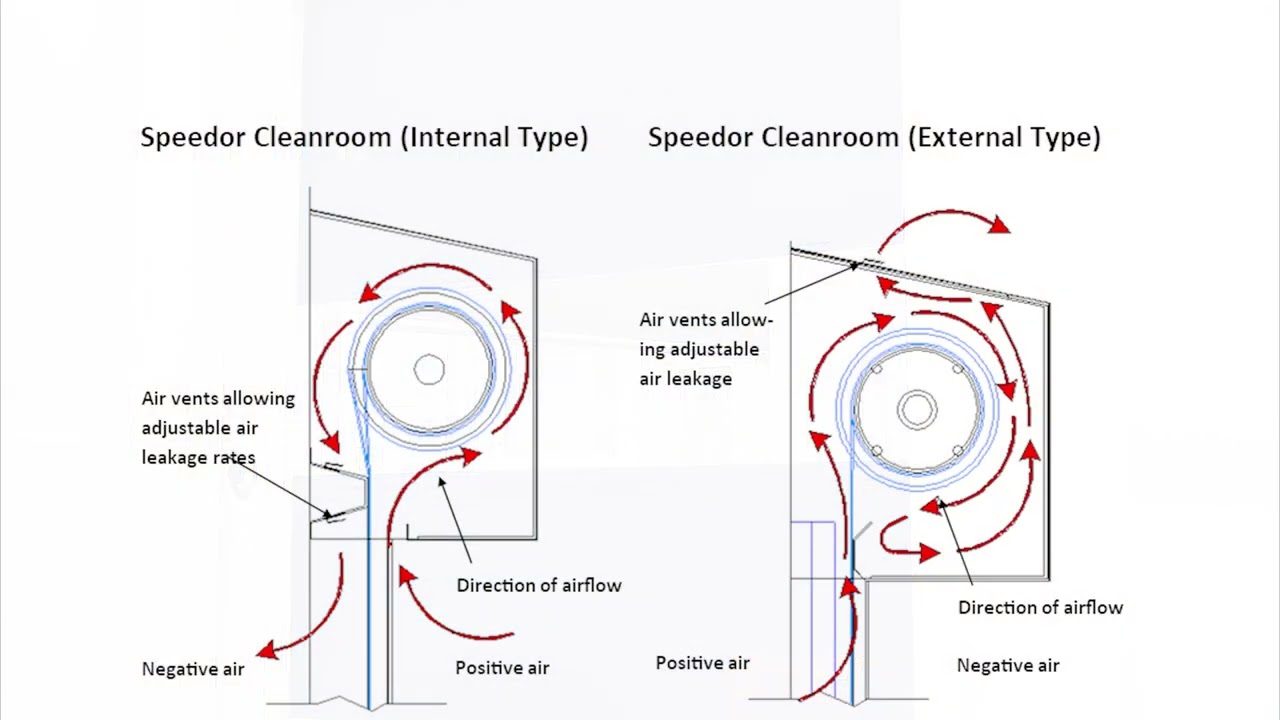

Hart Cleanroom flexible high-speed specialist doors, part of the high speed door range, are ideally suited to environments with strict air leakage requirements in which air pressure differentials need to be maintained. The Speedor Cleanroom is designed to work in these strictly controlled environments where hygiene standards are high, such as pharmaceuticals, food processing, electronics and micro-mechanics industries.

The main features of Cleanroom speed doors include maintaining strict air leakage requirements over specified pressure differentials. The intelligent control panel with digital display, reliable and clean in-line drive system complete with an integral safety brake and a non-touch safety light curtain ensures maximum protection to personnel. Seals minimise pressure drops and protect your environment against drafts, humidity, dust and dirt. The fast opening and closing speed of our pharmaceutical clean room doors help control airflow, reducing contaminants.

If you’d like to speak to us about how we can help you solve logistical challenges with a completely tailored clean room speed doors, please contact us today on +44 (0) 191 214 0404.

Size options

Up to 4m high

Up to 4m wide

Speed options

Standard opening – 1.0m sec

Standard closing – 0.4m sec

Variable speed options from 0.5mps up to 1.5mps

Colour options

Features and benefits of clean room speed doors

- Controlled air leakage.

- Maintain air pressure differentials.

- Gas containment.

- Compartmentalisation.

- Highest levels of safety to protect your personnel and equipment.

- Tested and certified for full compliance.

- Fast open and close for maximum environmental control and energy usage reduction.

- Technologically advanced features to boost efficiency.

Design options for Hart pharmaceutical clean room doors

- Size: custom- size up to 4000 mm.

- Speed: variable speed opening at up to 1.5m/s.

- Colour: yellow, blue, red, green, grey.

- Safety: optical touch sensitive safety bottom edge, safety photocells, movement sensors, presence sensors, laser detection, traffic lights, audible warning.

- Operators: push button, induction loop, photocells, movement sensors, pull cords, hand held or vehicle-mounted radio transmitters, radar.

- Vision panel.

Applications for clean room speed doors

- Pharmaceutical production.

- Medical production/ biotechnology production.

- Electronics / semiconductor production.

- Aerospace / automotive production.

- Chemical / environmental analysis.

Discuss the best product for your requirements

Contact us

Together we can help you choose the best industrial door solution for your premises.

Don’t just take our word for it…

Hart Doors offer you

1 year warranty as standard

CE / UKCA

mark

UK design and manufacture

LPCB

approved

High speed door case studies

Hart manufactured 20 doors for food processing facilities at Kerry Foods, including Speedor Storm, Speedor Mini and Speedor Cleanroom.

Read more...Hart manufactured, installed and serviced more than 70 industrial doors for pharmaceutical company Procter & Gamble across six sites.

Read more...We manufactured, installed and serviced industrial doors for DuPont, including Speedor Super, Speedor Storm, Speedor Mini and fire shutters.

Read more...